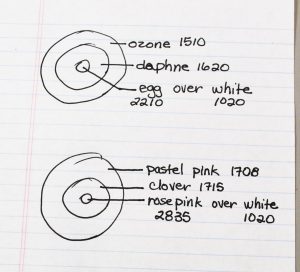

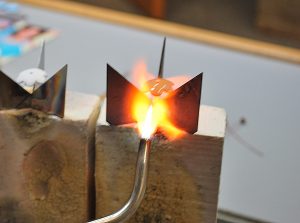

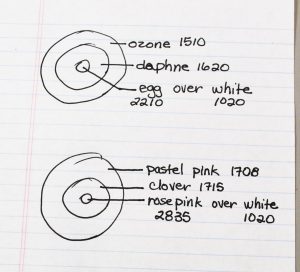

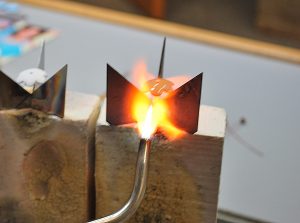

This is one of my first forays into the technique of torch firing enamels on my own after taking a class. I made these two pairs of enameled earrings in a day.

This is one of my first forays into the technique of torch firing enamels on my own after taking a class. I made these two pairs of enameled earrings in a day.

This is one of my first forays into the technique of torch firing enamels on my own after taking a class. I made these two pairs of enameled earrings in a day.

This is one of my first forays into the technique of torch firing enamels on my own after taking a class. I made these two pairs of enameled earrings in a day.